Alloy Enterprises introduced single-piece, leak-proof cold plates that deliver direct liquid cooling (DLC) to every component.

Alloy Enterprises introduced single-piece, leak-proof cold plates that deliver direct liquid cooling (DLC) to every component on the blade, including DIMMs, NICs, and QSFPs. The new design, produced using the company’s patented Stack Forging process, enables full-blade liquid cooling for the first time. This innovation helps to address the rising 100 kW peripheral heat bottleneck in next-generation 600 kW server racks.

As rack and power densities increase, the thermal balance inside high-performance servers has shifted. Traditionally, GPUs used about 80% of a blade’s total power, with the remaining 20% coming from DIMMs, NICs, QSFPs, and other peripherals, which are easier to cool with airflow.

Dr. Ali Forsyth, CEO and co-founder of Alloy Enterprises, noted that modern liquid-cooling technology now surpasses GPUs. It also cools the heat generated by other parts, such as the blade power. He said that traditional air cooling struggles to keep up with these rising heat sources. Forsyth explained that their single-piece cold plates ensure reliable liquid cooling for all components, providing full coverage at rack scale.

Keeping Up With Thermal Load

NVIDIA’s NVL72 rack, which operates at 120–140 kW, has peripherals that generate 24–28 kW, thereby maintaining airflow within acceptable limits. However, upcoming 600 kW-class systems, such as NVIDIA’s Kyber-based Rubin platform, could produce over 100 kW of heat solely from peripherals. This amount is four times the total thermal load of the current GPU racks and far exceeds what airflow cooling can manage. Without proper cooling, these peripherals create a bottleneck in the rack, affecting compute availability and revenue for data center operators.

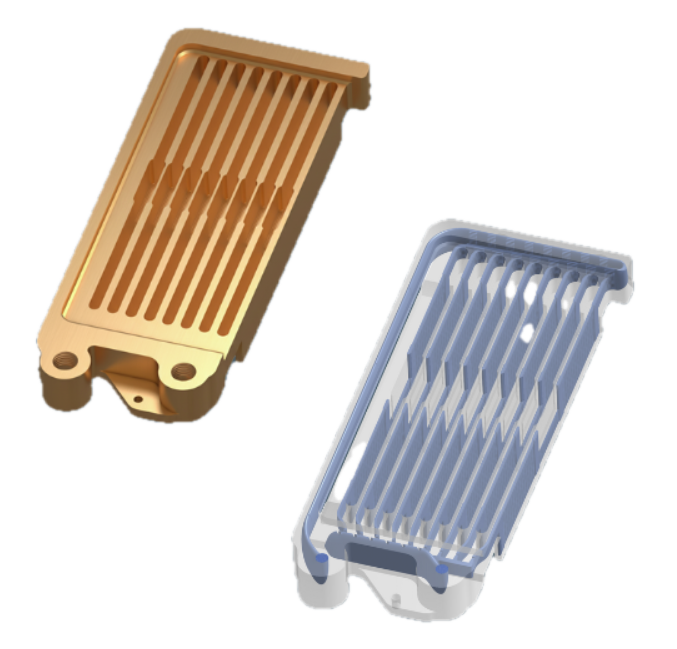

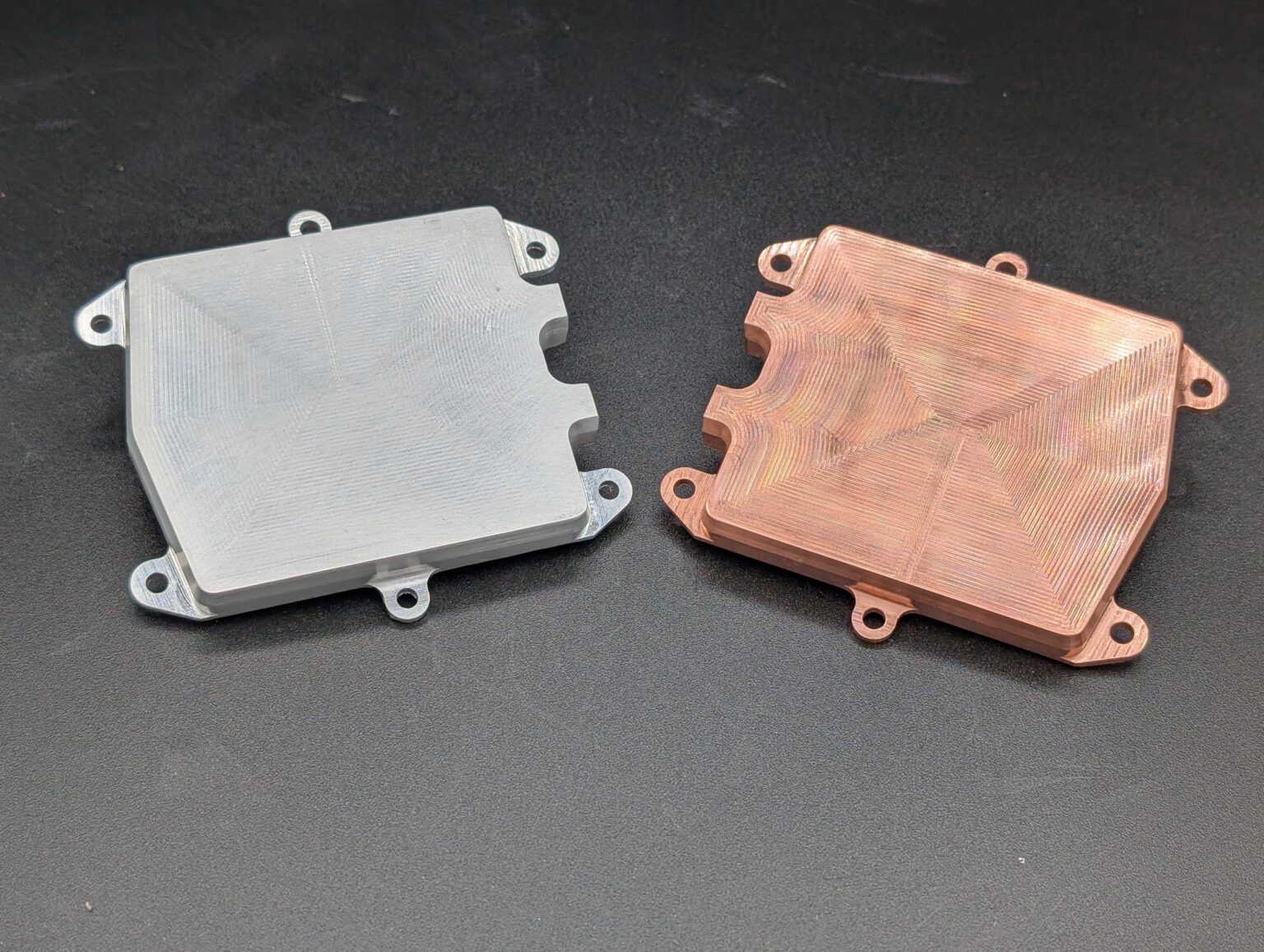

Alloy’s single-piece cold plates deliver the cooling needed for optimal computing, combining internal microgeometries with a monolithic design. This setup enables effective, high-pressure, leak-free cooling, where traditional brazed or soldered assemblies often fail. Rated to 2,000 psi without deforming, the plates maintain their shape even at extreme flow rates. Various plug-and-play microgeometries let Alloy target heat removal for each peripheral, optimizing performance within the power and space constraints of next-generation server blades.

Alloy’s Component-Specific Benefits

DIMMs

- Dual-sided cooling supports modules over 40 W, meeting next-gen JEDEC standards.

- Serviceable design allows replacement without draining the loop.

- Eliminates up to 32 solder joints, boosting reliability in dense arrays.

QSFPs

- Supports up to 50 W per port for 800G and 1.6T optical modules.

- Facilitates high I/O density with multiple ports per blade.

- Compact, single-piece design works with standard forms, eliminating bulky manifolds.

NICs & Specialty ASICs

- Cool the components with heat flux densities exceeding those of today’s leading GPUs.

- Low-profile, monolithic plates ensure uniform cooling and mechanical stability.

- Fits within tight board designs, maximizing both density and performance.

Engage with StorageReview

Newsletter | YouTube | Podcast iTunes/Spotify | Instagram | Twitter | TikTok | RSS Feed