As the StorageReview Test Lab continues to grow in terms of testing capacity and testing load at any given time, the cooling requirements and associated costs balloon as well. With 2,000-6,000 watts of compute activity throughout the week, or about 7,000 to 20,000 BTU of heating capacity, the costs just to cool the space can get quite hefty. The approach we've taken to address HVAC in our lab and building not only helps save us money, but literally heats our building during the heating months. While our needs may not be representative, most small data centers that start as telco rooms then grow into a rack or more of compute and storage, can have similar problems.

In the world of data center cooling, there are a number of options to remove a given amount of energy from an enclosed space and move it somewhere else. On the small scale there are portable chillers, like the Tripp-Lite SRCOOL12K we reviewed, as well as more permanent mini-split units and other more expensive dedicated cooling systems. When looking at the efficiency of each group, the more durable and long-term solutions work quite well, but cost quite a bit and require a large amount of energy to operate. For example, the 12K BTU portable chiller requires about 1200 watts to operate. While our initial approach was leveraging just a portable chiller, one route that we found worked best in our building was letting our under-utilized primary HVAC do the heavy lifting.

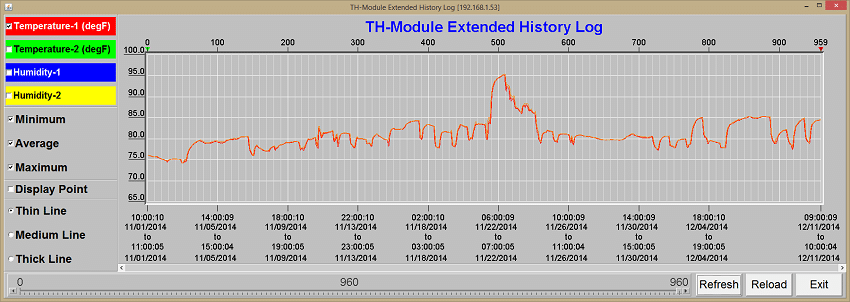

The initial plan with the portable chiller was dumping cold air into the room and pushing the hot exhaust from the chiller out, although as our lab grew we found temperatures quickly picking back up. Using the portable chiller, moisture is also constantly being removed from the air in the lab, lowering humidity levels and increasing static electricity. With the lab doors open and air free to circulate around the building, temperature levels in the lab could stay in the high 70s with minimal work from the HVAC. The only problem was getting the large volume of air from the lab into the ductwork. The solution leveraged high RPM in-line duct fans, mounted directly behind our racks, pushing the hot exhaust directly into our buildings HVAC return ducting.

Temperature as measured in the center of the rack

Currently the lab can handle upwards of 4,000 watts of overnight load (doors secured) staying in the low 80s (low 70s at minimal load) and under heavy daytime activity we've used over 8,000 watts without a problem. The power usage in our building has also dropped, since the in-line fan consumed ~120 watts instead of ~1200 watts of the portable chiller. Another huge advantage during winter months is instead of cooling the lab and paying to heat the building, the lab heats the building completely to a comfortable temperature of 74F. In fact our building AC turns on periodically throughout the winter to keep temperatures in check. Most importantly our electric bill is able to float between $500-600 throughout the year. Again, our needs and ability to be flexible to solve them may be unique, but there is more than one way to solve the small data center overheating issue if you're willing to be creative.

Amazon

Amazon