NVMe SSD Advanced Thermal Solution & System Integration Service for In-Vehicle Application Upscales Performance & Reliability

The demand to efficiently store high volumes of information from cameras is growing rapidly, from surveillance and factory automation to processing data for artificial intelligence (AI) applications. Market research firm Statistics MRC believes the global industrial machine vision market will expand from $8.54 billion in 2017 to $16.89 billion by 2026, while Allied Market Research predicts that the global automotive camera market will see annual growth of almost 10% to reach $24.1 billion by 2025.

Figure 1: The need to efficiently store high volumes of vision-based data is growing

In terms of AI, there has been an explosion of applications using machine learning, whereby patterns are identified by analyzing high volumes of vision-based data. These applications require reliable, high-capacity, high-performance storage.

We may still be a ways off from a fully-realized, self-driving car, but many luxury, top-of-the-line cars will offer self-parking features, made possible by cutting edge technology with sensors, visual data storage, and AI. As technology improves for transport field applications like surveillance, in-vehicle data logging, and auto-piloting, there is a significant and growing demand for efficiently storing high volumes of vision-based data. All of these applications require reliable, high-capacity, high-performance storage. In many cases, such systems may also need to operate in challenging environments with wide temperature ranges, strong vibration levels, considerable humidity, and/or unstable power supplies.

Consider, for example, the UPS truck driver going cross-country for hours on end in the middle of a freezing winter night. Or, a car sitting in traffic in the middle of downtown Los Angeles in sweltering summer heat.

In many cases, such systems may also need to operate in challenging environments, such as a manufacturing facility, the body of a vehicle or aircraft, or outdoors. While SSDs built on non-volatile NAND flash memory are the technology of choice, there can be issues when deploying SSDs in industrial or ‘non-consumer’ applications. On top of that NAND flash performance, reliability and endurance decreases as storage density increases.

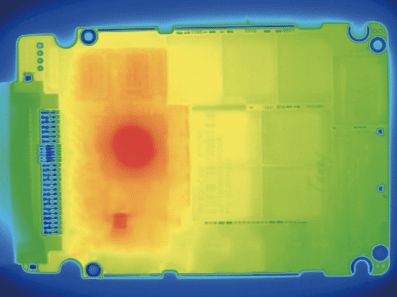

In one such case, Advantech supported a project involving in-vehicle video recording and a data-logging system. The requirements: a high-capacity data collection system in a very small form factor that would take advantage of the performance of PCIe SSDs using the NVMe communications protocol. Designed for global deployment, the complete system had to operate at temperatures ranging from -20C up to 70C. While applying multiple NVMe SSDs in a system provides excellent throughput with strong performance, putting together 6 to 12 pieces of the high power consumption NVMe SSD also generates substantial heat. Due to the fact that the system had to be very compact and needed to fit into in-vehicle applications, heat dissipation was a major obstacle.

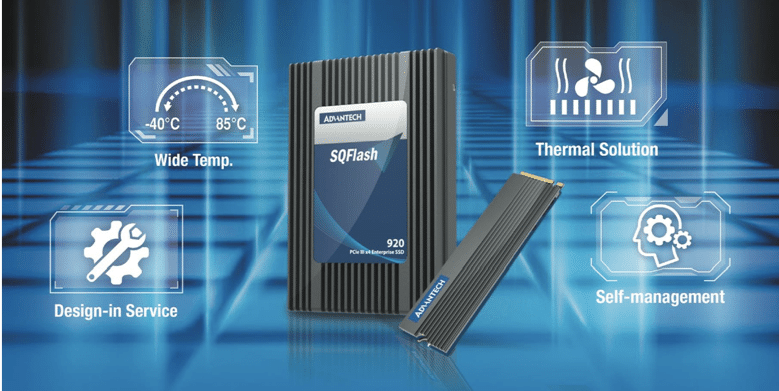

In this case, Advantech’s SQFlash 920 NVMe SSDs provided the perfect solution. The SSDs used Toshiba’s BiCS 3D NAND flash technology, supported capacity of up to 8 TB per drive, and came with built-in power failure protection and advanced security technologies.

Figure 2:Advantech’s SQFlash SSD

- Power Failure Protection: When the voltage drops below 2.9V, the controller stops all memory activity to prevent invalid data being written or accessed. Once power is restored, a data integrity check assesses data validity and takes corrective action to eliminate the possibility of incorrect data resulting from a non-complete write to flash.

- Power Drop Catcher: Even a power drop of less than 1ms (not unusual in many industrial scenarios) can impact read/write functionality or cause devices to freeze. With Power Drop Catcher an embedded reset IC constrains reset timing to handle the glitches that could result from voltage drops.

- Flush Manager: DRAM deployed to boost SSD performance and endurance by acting as a cache between the controller and the storage needs to be powered. Flush Manager delivers data integrity by ensuring valid data is only stored in the flash memory and not the cache in the case of a power failure or unstable power supply.

- Voltage Stabilizer: Based on a tantalum capacitor array, this integrated function maintains a stable power supply to both the flash memory and the DRAM cache when the built-in voltage detector detects unstable power input (below 4.75 V or above 5.25 V).

Keeping the stored data secure was another important consideration. SQFlash SSDs addressed this through a variety of advanced data security capabilities ranging from functions that lock read and write commands via an SSD firmware setting to rapid or emergency erase options.

This high-performance and ruggedized NVMe SSDs solution proved to be ideally suited to the customer’s requirements. Advantech’s design-in capabilities and manufacturing services also helped improve the time-to-market for the customer’s newest product release. Overall, the customer was very satisfied with Advantech’s solution for this incredibly important emerging use case.

Amazon

Amazon