As AI and HPC workloads continue to scale, so do their power and cooling demands. Modern GPUs, including NVIDIA’s RTX PRO 6000 Blackwell Server Edition, can draw up to 600W, placing enormous thermal strain on traditional data center infrastructure. While air-cooled servers can handle these GPUs, maintaining stable performance at this level of density is another matter entirely. The cost of moving air through racks filled with high-wattage GPUs rises steeply, particularly in regions with high electricity rates, such as northern Europe, the US Northeast, and parts of Asia-Pacific. In these markets, immersion cooling delivers a measurable operational and economic advantage.

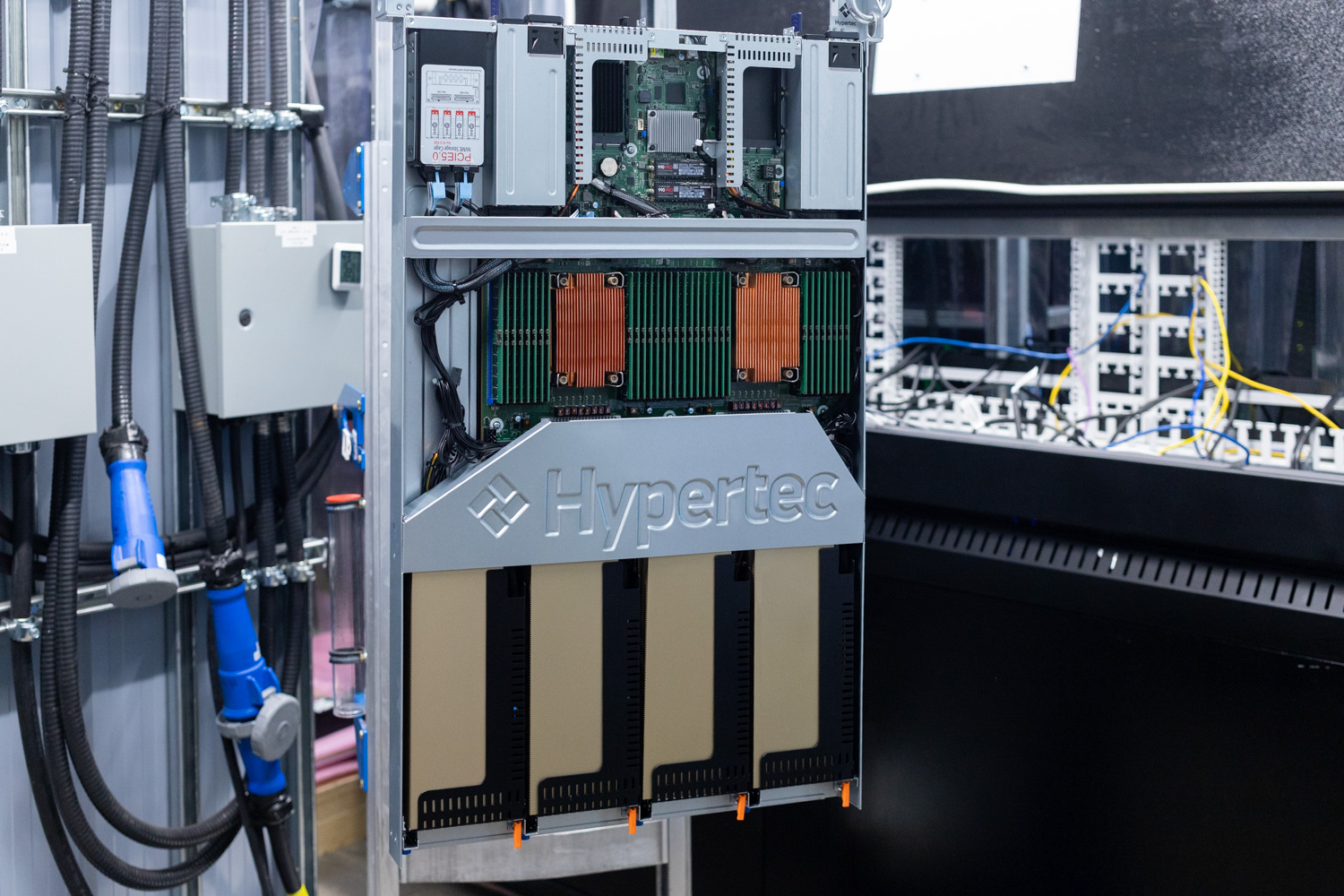

Hypertec’s Trident iGW610R-G6 server was designed with this reality in mind. Unlike retrofitted servers that adapt air-cooled designs to fluid environments, the Trident family of servers is immersion-born, engineered from its first PCB layout to operate in dielectric fluid. This new 1U Hypertec platform supports up to four full-height, full-length GPUs in a 21-inch OCP layout, striking a balance between compute density and stable thermal behavior.

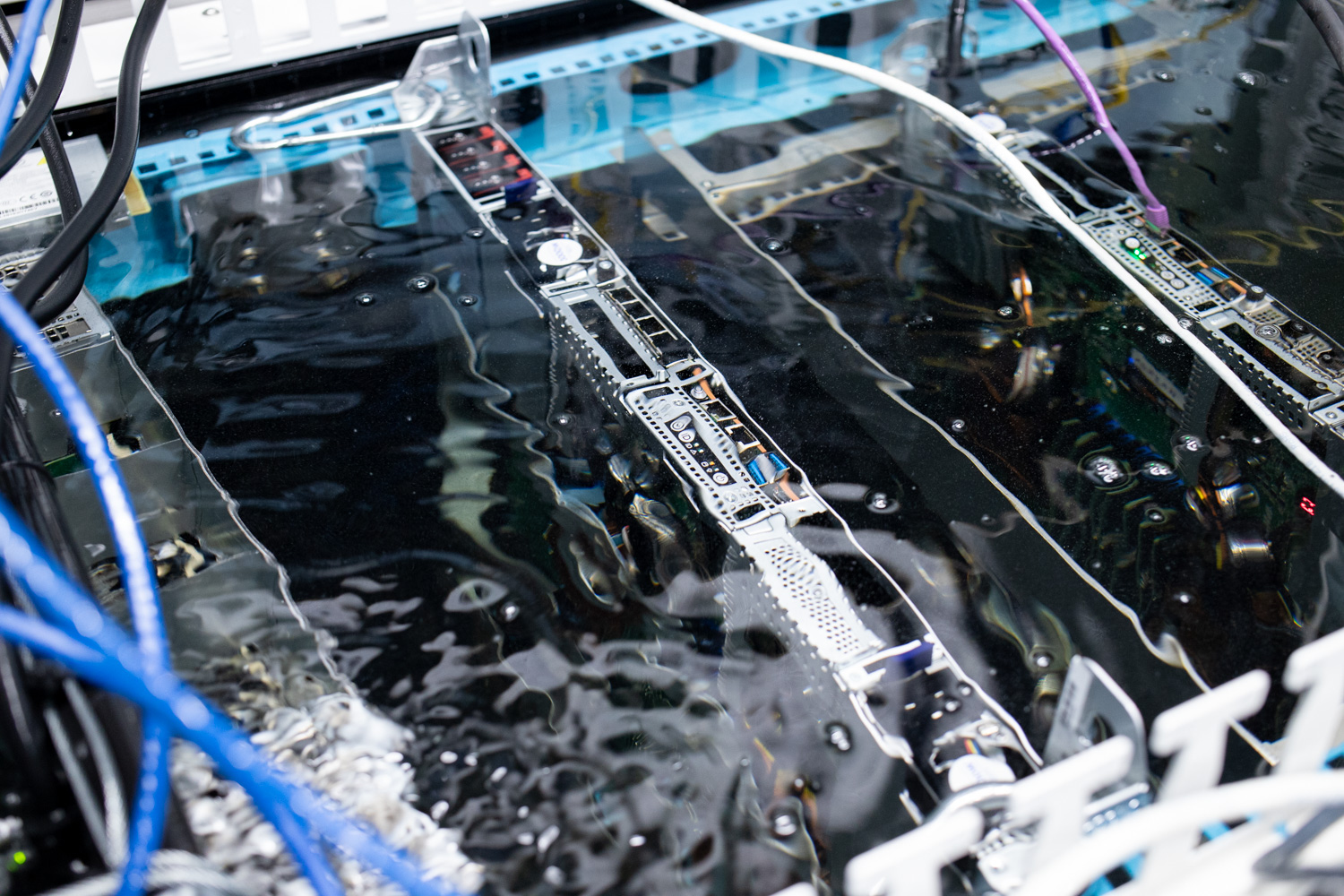

We evaluated the Trident iGW610R-G6 in Hypertec’s Montreal lab, initially conducting remote testing before moving on-site to record and observe the system in action. The configuration under test consisted of a single NVIDIA H100 GPU and Solidigm SSDs, operating within a Submer immersion tank filled with Castrol dielectric fluid. Across sustained workloads, the Trident maintained a remarkably stable temperature profile, with component deltas staying within a narrow range. This consistency significantly reduces thermal cycling, the root cause of many long-term reliability issues in high-performance systems.

The benefits of immersion extend beyond temperature control. With stable thermal conditions, GPUs can maintain peak boost clocks without throttling, CPUs operate with lower variability, and storage devices deliver consistent I/O throughput. This uniformity translates into greater reliability, predictable performance, and more efficient energy utilization per rack unit —key outcomes for organizations building large-scale AI and HPC environments.

This evaluation builds on our prior collaboration with Hypertec, detailed in Edge AI Anywhere: This Immersion-Cooled Mobile Data Center Makes It Possible. That project showcased the promise of mobile AI infrastructure at the edge through immersion. Here, the focus shifts to fixed-data-center deployment, demonstrating how the Trident iGW610R-G6 and its surrounding ecosystem from Submer and Castrol deliver practical, rack-scale efficiency for dense GPU computing.

TRIDENT iGW610R-G6 Design and Build

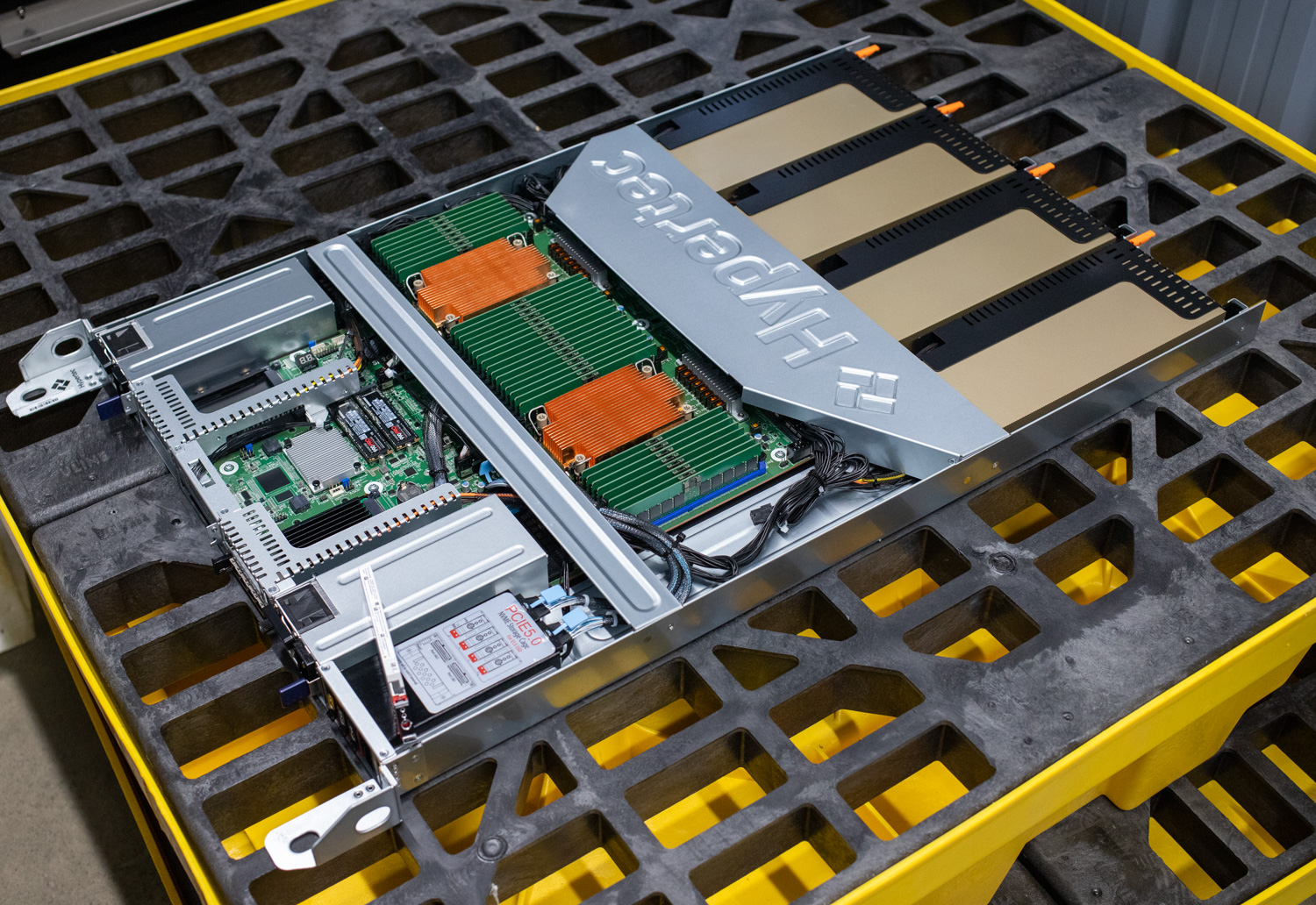

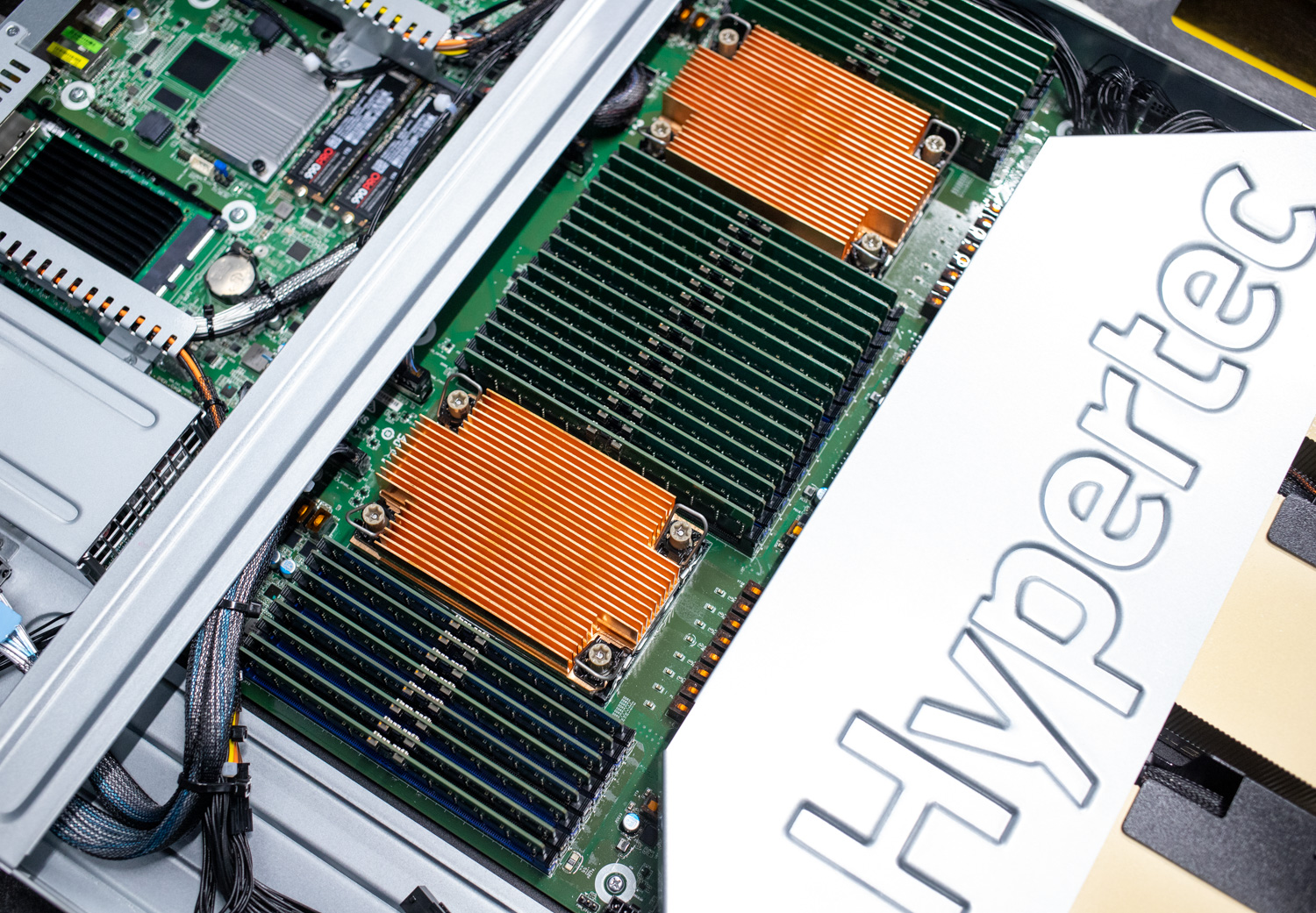

The TRIDENT iGW610R-G6 takes a distinctly different approach from conventional air-cooled rack servers. At first glance, you will notice it lacks a traditional top cover, leaving the major components fully exposed to the immersion fluid. This open-chassis design maximizes surface area contact for efficient heat transfer within the dielectric fluid, eliminating the need for internal fans or air channels. Every aspect of the system is engineered for single-phase immersion cooling, in which thermal energy is uniformly absorbed and carried away by the surrounding fluid rather than airflow. The result is a silent, vibration-free platform optimized for dense, high-performance compute environments.

Physically, the chassis retains a 1U form factor, measuring 33.46 × 21.06 × 1.75 inches and weighing around 72 pounds (32.6 kilograms) when fully loaded. Despite its low profile, the layout is remarkably serviceable, with four front-accessible E1.S NVMe bays and easily reachable PCIe slots positioned for quick component swaps inside the tank. The design integrates directly with leading immersion tank systems, providing plug-and-play compatibility without specialized hardware enclosures or airflow controls.

Our test unit was configured with dual Intel Xeon 6530 processors, each featuring 32 cores and 160 MB of cache, with a TDP of up to 350 watts per socket. Cooling is handled by custom immersion-optimized solid-copper heat sinks with indium-foil thermal interface material, ensuring efficient thermal transfer to the fluid. The CPU complex is paired with 32 DDR5 RDIMM modules (each with 32 GB capacity) running at 4800 MT/s, providing ample bandwidth for AI, HPC, and data analytics workloads.

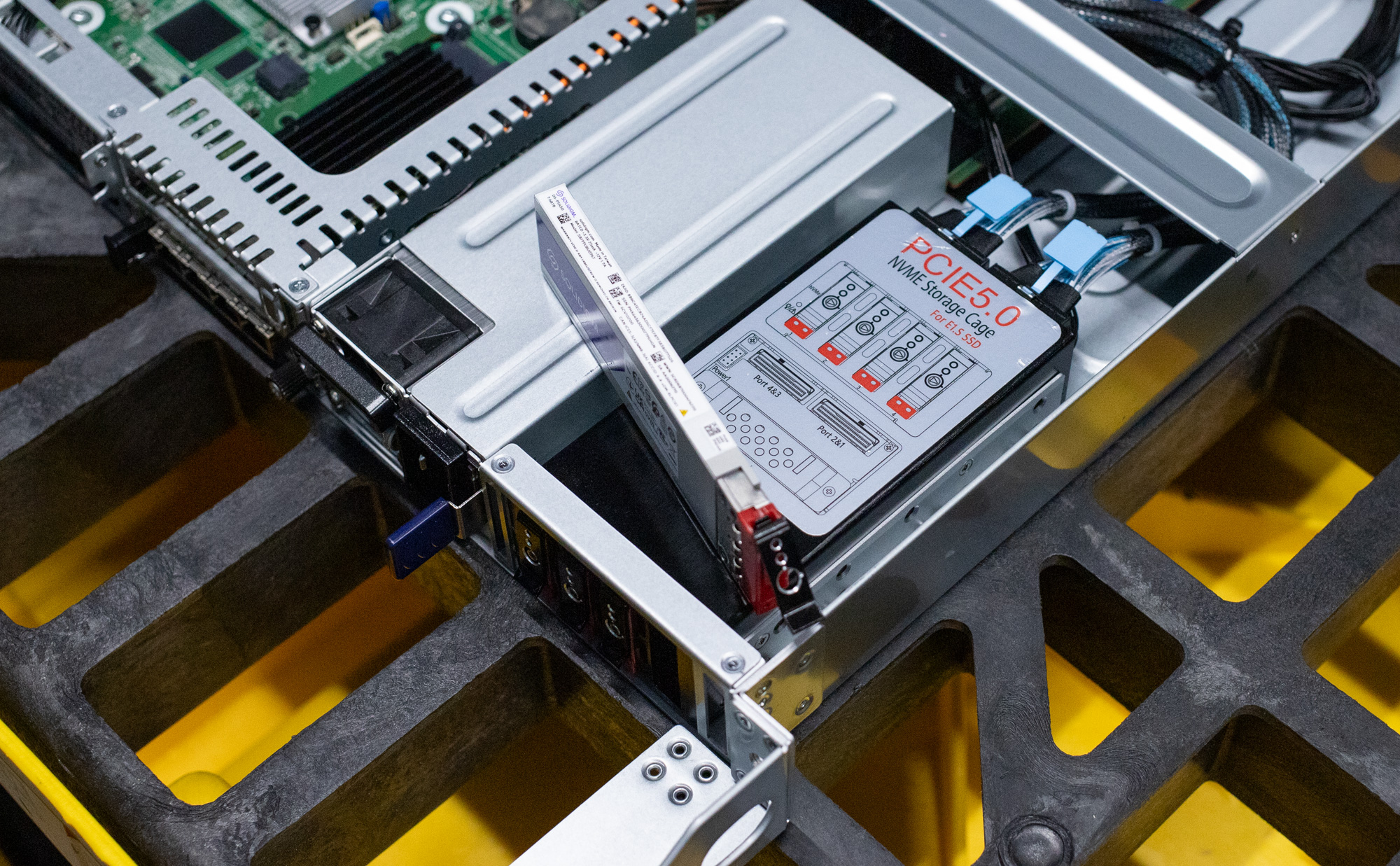

Storage configuration is a key strength in this build. Alongside two 1TB M.2 NVMe SSDs for the operating system, the system houses four Solidigm D5-P5430 E1.S 7.68TB drives as the primary data tier. These EDSFF drives deliver both high density and impressive efficiency, leveraging PCIe 4.0 performance in a compact footprint. The E1.S form factor is ideal for immersion environments, where front-serviceable drive trays allow tool-less swaps without draining or lifting the chassis. The Solidigm drives also contribute to the server’s overall balance between speed, endurance, and thermal efficiency, making them well-suited for AI model storage, data staging, and high-throughput inference pipelines.

The system supports up to four double-width accelerators, enabling users to scale compute density as needed. Networking is enabled by a dual-port 10GBase-T OCP 3.0 module that supports 1GbE, ensuring broad compatibility with existing data center fabrics.

Power delivery is provided by 1+1 redundant 3000W 80 PLUS Titanium CRPS power supplies, offering consistent performance under heavy loads while maintaining high-energy efficiency. Because the server is fully submerged, no active airflow is required, resulting in zero fan noise and no dust accumulation. This design not only simplifies maintenance but also extends component lifespan and improves overall reliability.

Hypertec estimates that immersion deployments of the iGW610R-G6 can achieve a 95% reduction in cooling operating costs and up to a 60% increase in hardware longevity, with an independently certified PUE of 1.03. Combined with the energy reuse potential of capturing up to 99 percent of waste heat, the system demonstrates how performance density and sustainability can coexist effectively.

TRIDENT iGW610R-G6 Management Overview

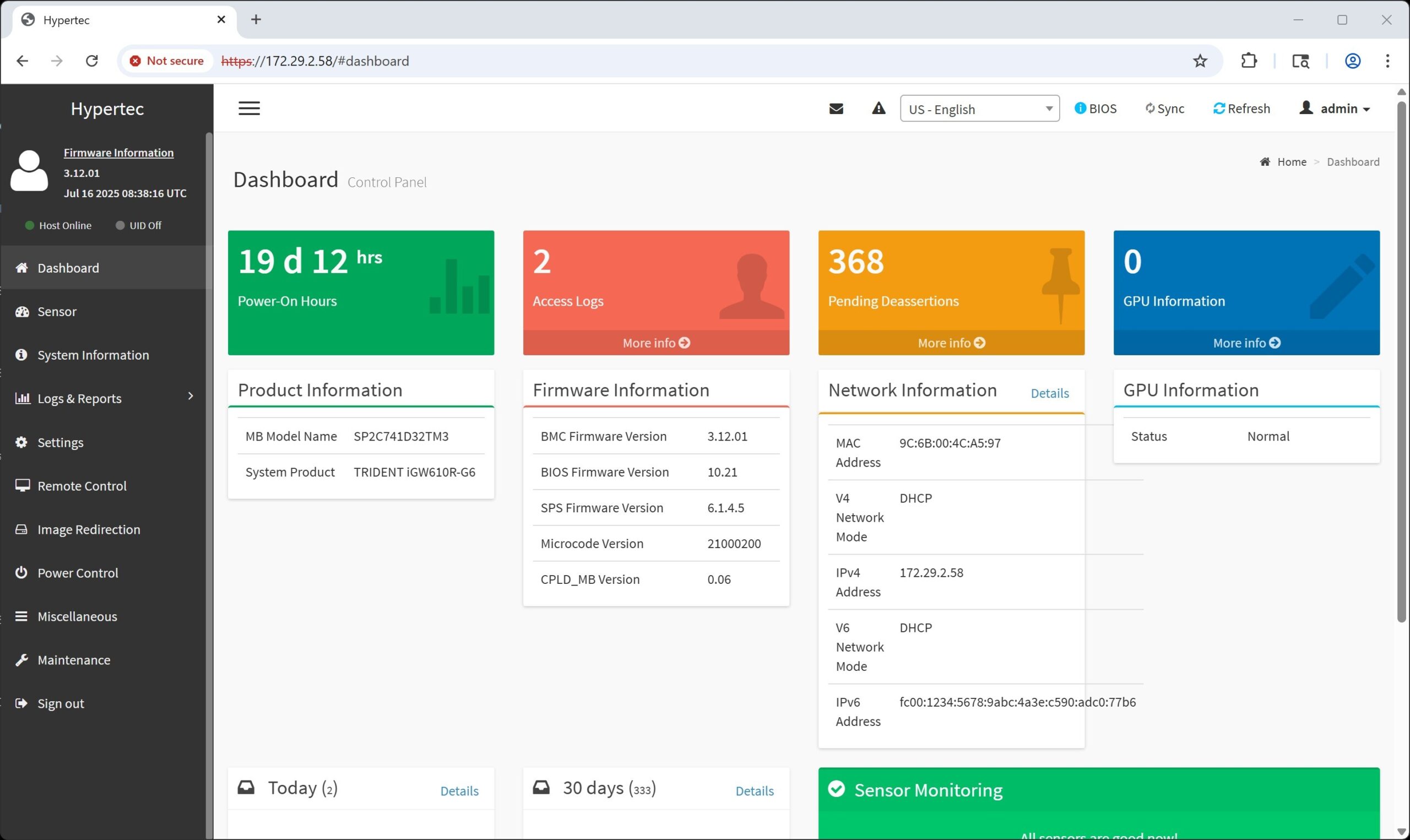

The TRIDENT iGW610R-G6 is built on a board powered by an ASPEED AST2600 Baseboard Management Controller (BMC), providing full IPMI 2.0 compatibility with iKVM and virtual media support. This out-of-band management platform enables administrators to monitor, configure, and remotely manage the system regardless of its operating system state. These functions are essential for high-density and immersion-cooled deployments.

The web-based interface is clean and easy to navigate, with the left-hand panel giving quick access to Dashboard, System Information, Sensor, Logs and Reports, and Power Control sections. Each area provides detailed visibility into system health, sensor data, firmware levels, and power states. The dashboard displays uptime, access logs, and component information at a glance, providing a clear overview of system status without requiring additional software.

When operating in an immersion environment, these remote capabilities are especially valuable. Instead of physically inserting media or peripherals into the oil tank, administrators can deploy operating systems, mount images, and perform updates via virtual media. This reduces maintenance time and keeps submerged hardware operations clean, efficient, and safe.

Dashboard System Overview

The main dashboard shows power-on hours, firmware versions, network details, and GPU health. It serves as a central status panel for the TRIDENT platform, with the BMC providing temperature, voltage, and sensor telemetry accessible via IPMI commands or SNMP monitoring tools.

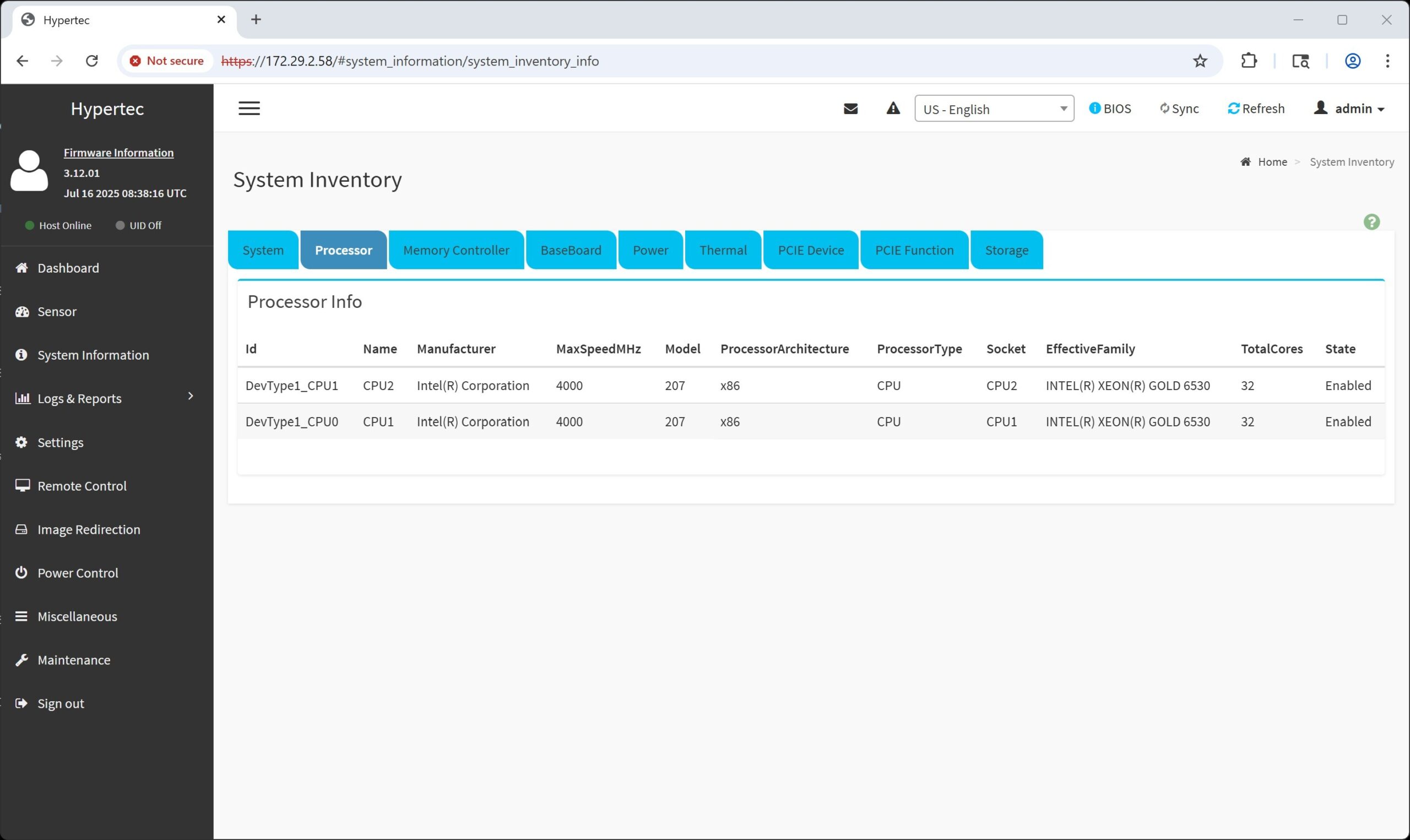

Processor Inventory

The Processor page lists each socket, including its model, core count, and status. This unit is equipped with two Intel Xeon Gold 6530 processors. Each processor features 32 cores, uses the x86 architecture, is installed in CPU1 and CPU2 sockets, and is enabled. The page reports a maximum speed of 4,000 MHz and confirms the architecture and family, making it easy to validate that both CPUs are present, healthy, and running the expected microcode.

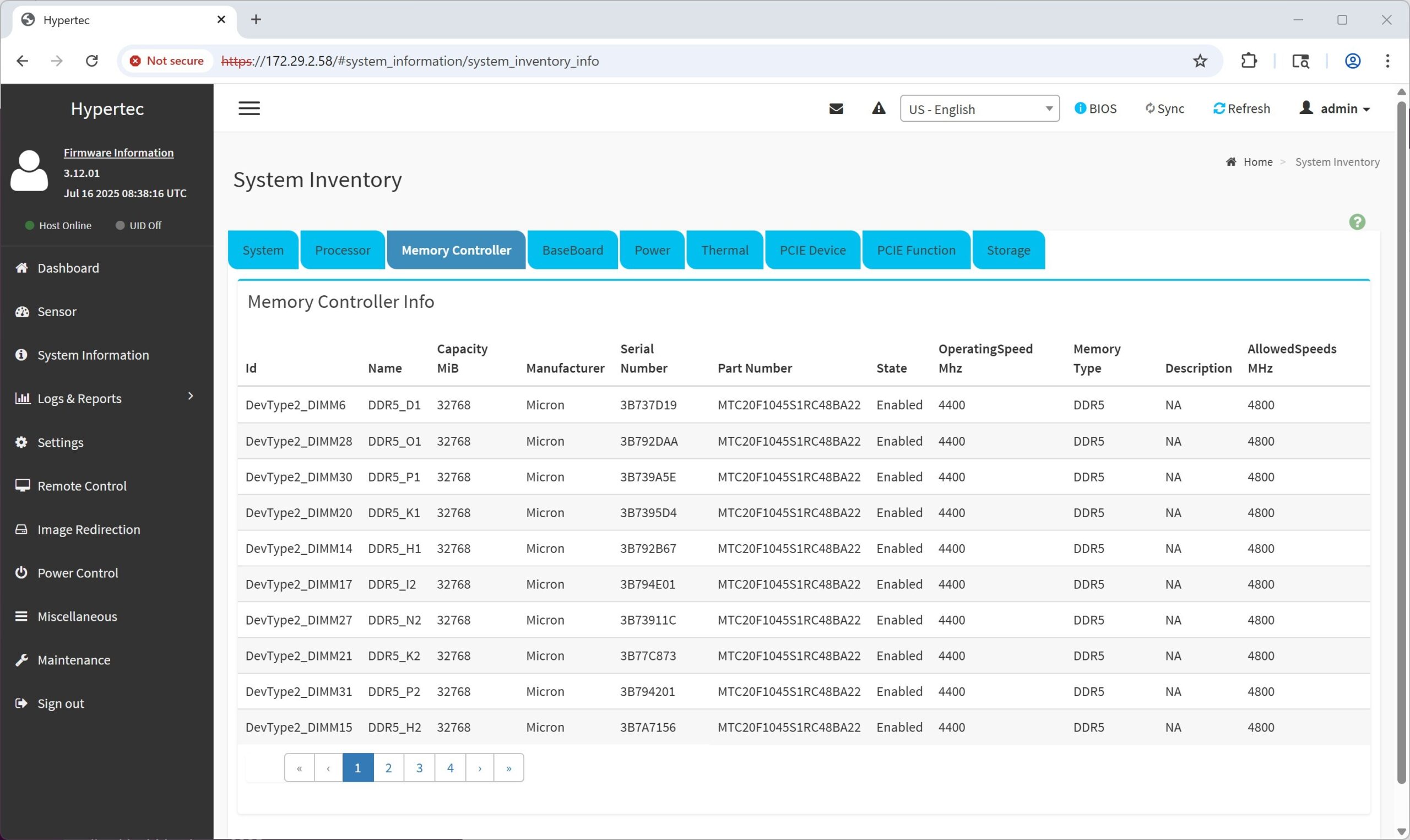

Memory Controller Inventory

The Memory Controller page displays all DIMMs, including their capacities, vendors, serial numbers, part numbers, states, and operating speeds. In our configuration, each slot is populated with Micron 32,768 MiB DDR5 RDIMMs (part number MTC20F1045S1RC48BA22), which are enabled and operate at 4400 MHz, with a maximum allowed frequency of 4800 MHz.The table view makes channel population checks straightforward and helps confirm uniform timings across all banks.

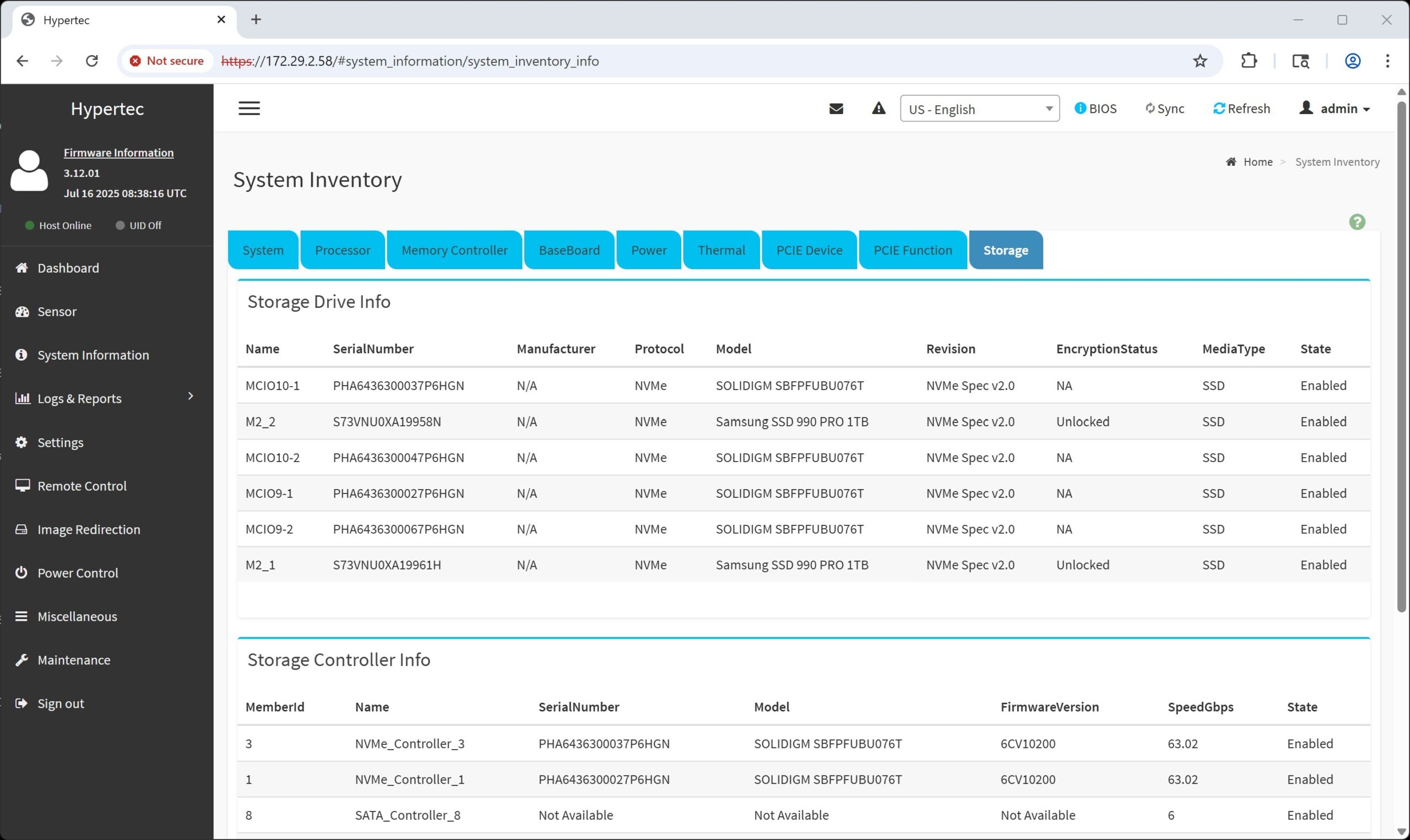

Storage Inventory

The Storage tab displays connected drives and controllers. In our system, we can see our Solidigm D5-P5430 E1.S NVMe SSDs are used for primary storage, while Samsung 990 Pro 1 TB M.2 drives handle the operating system. Each drive’s firmware revision, interface speed, and encryption status are displayed, simplifying verification of the storage subsystem without opening the chassis.

TRIDENT iGW610R-G6 Thermal Performance

Thermal behavior plays a crucial role in long-term system reliability, and the Hypertec Trident iGW610R-G6 was engineered with immersion operation in mind. Rather than relying on air movement over heatsinks to remove energy from high-density components, the Trident operates fully submerged in a dielectric liquid that conducts heat directly from the hardware into a managed cooling circuit. This design eliminates the mechanical risks commonly associated with air-cooled systems, such as fan failure, dust contamination, and humidity exposure. By isolating the electronics from air and introducing a continuous liquid heat path, the system maintains a highly controlled and consistent thermal environment.

During testing, the Trident iGW610R-G6 operated inside a Submer SmartPod Exo tank configured for single-phase immersion cooling. In this setup, the dielectric fluid continuously circulates across the chassis, absorbing heat from the CPU, GPU, and NVMe drives before passing through integrated heat exchangers. The captured heat is then transferred into the facility’s chilled-water loop, which carries it away to the building’s heat-rejection infrastructure. This closed-loop design maintains steady-state temperatures across the rack, ensuring uniform coolant flow and preventing hotspots that often occur in dense compute configurations.

The circulating fluid acts as a thermal reservoir with a high specific heat capacity. As heat loads change, the liquid absorbs and redistributes energy evenly throughout the tank. This minimizes temperature gradients and prevents component-level fluctuations common in air-cooled data centers. In traditional environments, changes in room temperature or fan speed can cause a swing of several degrees on sensitive components. Over time, those cycles create physical stress in solder joints and substrates. In immersion, that effect is nearly eliminated, reducing mechanical fatigue and extending the hardware’s lifespan.

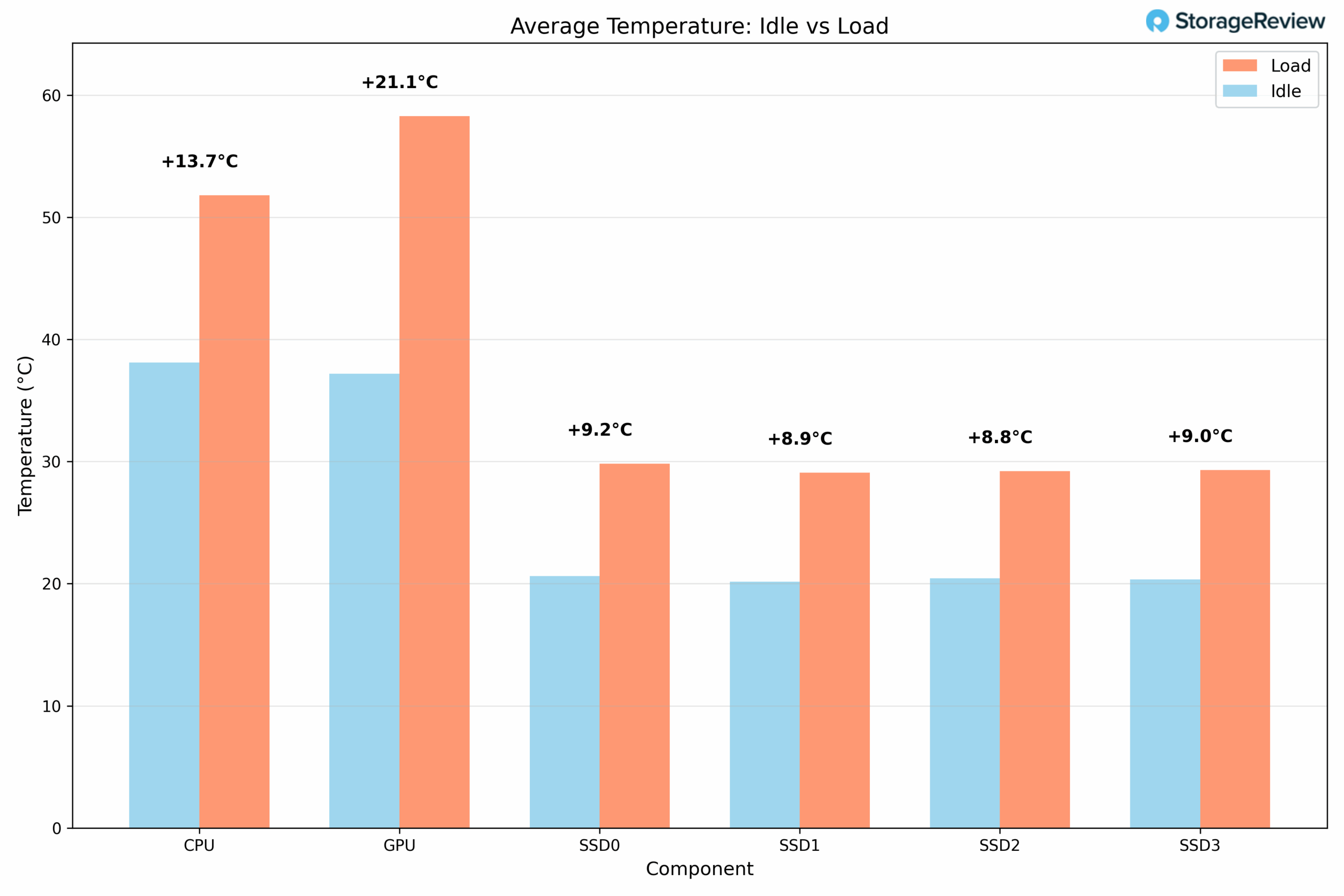

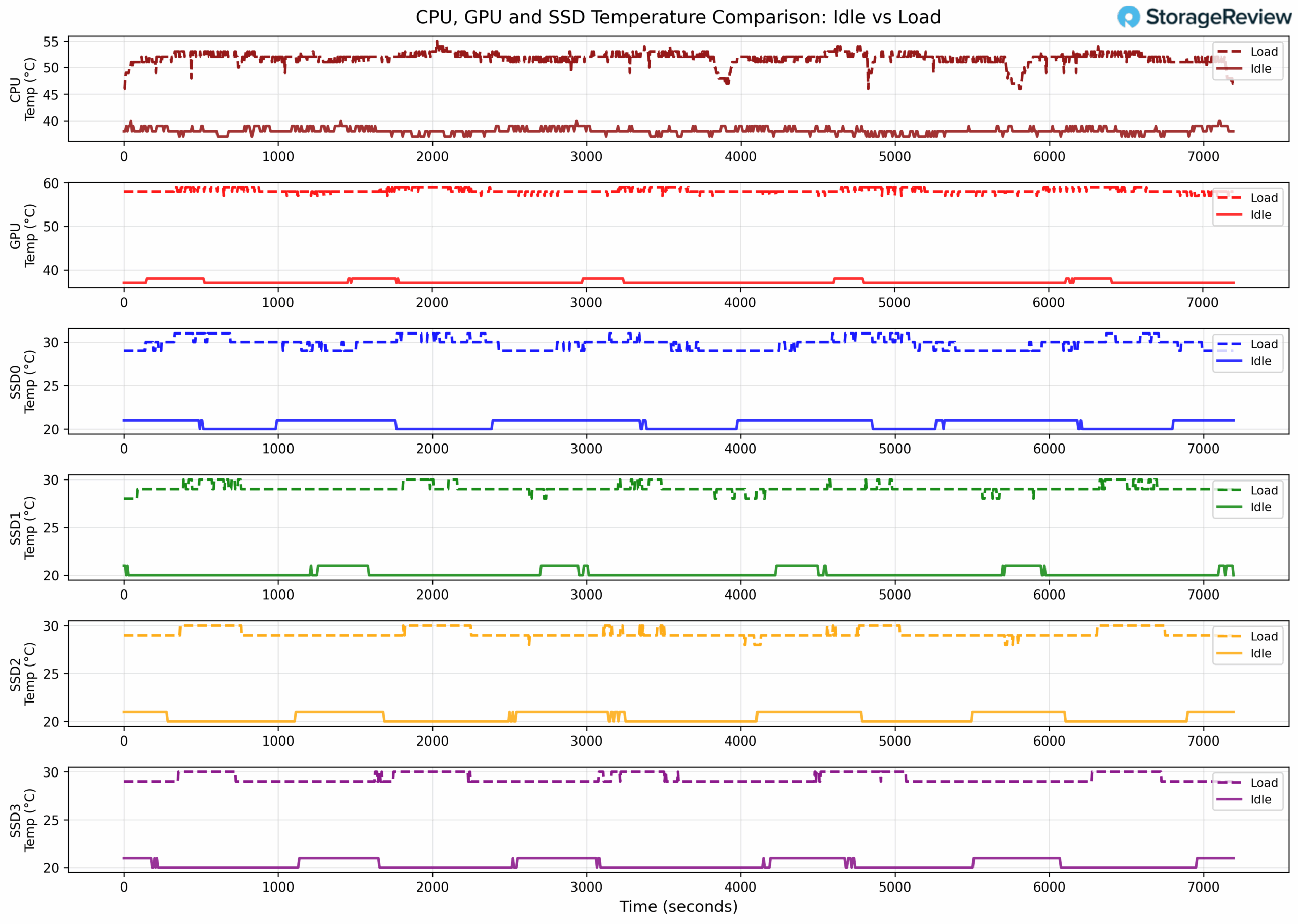

To measure thermal behavior under heavy workloads, the Trident iGW610R-G6 was stressed across all major subsystems. FIO was used to apply continuous I/O pressure to each SSD, while GPU and CPU stress tests were applied to ramp those respective components to 100%. Throughout the run, component temperatures were logged over several hours to evaluate equilibrium and fluctuation characteristics.

The results were highly consistent. The CPU stabilized at approximately 52° C, roughly 13.7° C above idle. The GPU peaked around 58° C, showing a 21.1° C rise. Each of the four Solidigm NVMe SSDs followed similar trends, maintaining a temperature range of 29° C to 30° C under load, with deltas of 8.8° C to 9.2° C. Once equilibrium was reached, temperatures remained flat for the duration of the test with minimal variation, indicating even fluid distribution and effective heat extraction through the facility loop.

The time-series data confirms this performance. After an initial warm-up phase, all sensors display steady, nearly horizontal temperature lines. There are no large oscillations or thermal drift events, indicating that immersion cooling maintains a consistent temperature and that the chilled-water loop efficiently dissipates heat from the tank. The Trident’s thermal profile remained remarkably predictable even under sustained full-load operation.

From a reliability perspective, this stability carries significant benefits. The absence of fans reduces maintenance on moving parts, while the sealed environment prevents dust ingress and oxidation of connectors. Over time, these characteristics translate to lower failure rates and improved mean time between service events. The combination of the Trident iGW610R-G6 platform and Submer’s single-phase SmartPod Exo environment provides a repeatable and resilient cooling solution that scales well for dense deployments.

Overall, the thermal data collected from the Trident iGW610R-G6 illustrates how immersion cooling with active liquid circulation delivers not only superior heat management but also a measurable reliability advantage. By maintaining consistent component temperatures and eliminating ambient dependencies, the system operates within optimal limits regardless of workload or duration, making it well-suited for high-availability compute and storage workloads.

Why Organizations Are Choosing Immersion

Immersion cooling is no longer experimental. Organizations building large-scale AI and HPC environments are deploying it today to achieve stable thermal performance, higher rack density, and more efficient use of power and facility resources. The following examples illustrate how immersion-born platforms are being adopted in production environments at a meaningful scale.

ADACEN

ADACEN selected immersion-born infrastructure to support the expansion of its AI and HPC-as-a-service platform, enabling the organization to run dense GPU configurations while simplifying facility cooling requirements and improving long-term operational efficiency.

“We partner with Hypertec because their immersion-born technology gives us an operational and sustainability advantage that air or direct-to-chip liquid cooling simply can’t deliver. Their fully engineered immersion platforms allow us to deploy higher-density CPU and GPU resources, reduce cooling energy by over 90%, and eliminate mechanical points of failure. Hypertec’s systems enable us to scale our AI/HPC as-a-service workloads efficiently while meeting our performance and ESG goals—that’s why they’re a core part of our AI strategy.” – Bernard Westwood, Director of Revenue Operations, ADACEN.

ADACEN represents one model of high-density deployment in hosted infrastructure. Research computing environments show similar drivers and outcomes.

University of Waterloo

The University of Waterloo is deploying 700 nodes across nine immersion tanks to support next-generation research computing. The move to immersion enables high-density GPU clusters with consistent thermal behavior and reduced facility complexity.

“With Nibi, we chose immersion cooling because it offers exceptional efficiency and reliability while simplifying our data centre design. Hypertec’s immersion-born servers have made it easy to deploy high-density compute without the complexity of traditional air or liquid cooling systems. This approach improves performance and stability and supports our goal of building a very sustainable, energy-efficient HPC environment.” – John Morton, Director of Technology at SHARCNET, University of Waterloo.

These deployments demonstrate that immersion is already being used to deliver predictable performance at scale, and they represent just two of many organizations adopting this approach.

Conclusion

Our evaluation of the Hypertec Trident iGW610R-G6 revealed that immersion cooling yields consistent performance gains for dense GPU and storage configurations. Across sustained workloads, the system maintained narrow, stable temperature deltas with no thermal drift or oscillation. CPUs and GPUs held consistent operating points under load, and the Solidigm E1.S drives delivered steady I/O throughput with only minor temperature variation. This level of thermal consistency directly reduces stress on components and minimizes the conditions that typically drive premature wear.

These findings align with what large operators are reporting in production environments. ADACEN reports a measurable reduction in annualized failure rate (AFR) in immersion deployments, driven by reduced thermal cycling and the elimination of fan vibration and particulate exposure. The result is improved reliability over time, reduced maintenance frequency, and greater service continuity at scale.

The University of Waterloo’s deployment of 700 nodes across nine immersion tanks further reinforces that immersion cooling is being adopted as a practical strategy for building and expanding high-density compute clusters. The operational efficiencies, performance stability, and simplified facility requirements make it well-suited for organizations planning to run AI and HPC workloads at scale.

Immersion cooling is already delivering stable performance and operational efficiency in production environments. As compute density and power consumption continue to increase, immersion-born platforms like the Trident iGW610R-G6 offer a practical and sustainable path forward for large-scale AI and HPC deployments.

This report is sponsored by Solidigm. All views and opinions expressed in this report are based on our unbiased view of the product(s) under consideration.

Amazon

Amazon