The Eaton In-Row Precision Cooling System is designed for targeted, rack-level cooling in environments where precision, efficiency, and space utilization are paramount. Designed for small to mid-sized data centers, high-performance computing rooms, and edge deployments, the unit delivers up to 25.8 kW (88,000 BTU/hr) of active cooling while occupying a footprint only 300mm (or 11 inches) wide. That makes it slim enough to fit directly in line with rack cabinets, capturing heat right at its source instead of relying on room-scale air distribution.

Eaton In-Row Precision Cooling System Features

In-row cooling, like this, can be especially valuable for businesses running mixed-density racks, as it helps avoid overcooling low-density areas while ensuring high-density racks receive the necessary cooling without competing for airflow. The close-coupled approach is approximately 25% more energy efficient than traditional perimeter CRAC units, which directly translates into lower power costs over time and reduced strain on facility-wide HVAC systems.

Cooling is handled via direct expansion (DX) technology, which uses refrigerant to absorb heat directly from the air rather than relying on a separate chilled water loop. This is paired with a rotary inverter-driven compressor that can adjust its speed to match the current cooling demand, helping reduce both energy consumption and mechanical wear. Air movement is generated by six electronically commutated fans, which utilize brushless DC motors with built-in speed control for enhanced efficiency and more precise airflow management compared to conventional AC fans. Together, these components can deliver up to 2,950 cubic feet per minute of airflow, allowing the unit to maintain a steady supply air temperature between 18°C and 27°C, depending on the heat load.

This system utilizes R410A refrigerant, a standard choice for equipment in this class. It’s non-ozone-depleting, widely available, and generally straightforward for technicians to work with. On the power side, the unit can draw up to 10 kW of power, running on a 208V three-phase power supply at 60 Hz, with a peak current of 27 amps.

Remote management comes standard with the integrated WEBCARDLXMINI network interface, giving facilities teams 24/7 visibility and control via HTTP(S), SSH, Telnet, or SNMP. This enables the receipt of alarms, adjustment of settings, and review of logs without being physically present, which is particularly valuable for unstaffed edge locations or facilities where site visits are costly and time-consuming. SNMP support also enables the unit to integrate directly with DCIM (Data Center Infrastructure Management) software for centralized monitoring across multiple sites.

Maintenance features include hot-swappable fans to help reduce downtime, an automated condensate pump capable of moving water horizontally up to 45 meters or lifting it vertically up to 8 meters, and a 1/4-inch condensate drain connection. The pump’s automatic level detection helps prevent the risk of overflowing, which can be critical in environments where even small leaks could cause damage to equipment. The 68 dBA sound rating at 1 meter is typical for in-row cooling of this capacity; it’s not whisper-quiet, but in a typical data hall, the ambient noise level means it won’t be the dominant source.

Condenser

The Eaton In-Row Precision Cooling System utilizes an outdoor condenser, connected via copper refrigerant lines, to reject heat directly outside. This approach avoids the complexity of ductwork or raised floors, allowing the unit to operate independently of the building’s central HVAC system. Condenser placement can be above or slightly below the indoor cooler. It can be installed in horizontal or vertical orientations, though vertical lift limits must be observed for proper refrigerant return.

Eaton stresses that keeping the condenser coil clean and the fan operational is critical for efficiency, as issues can trigger alarms for high discharge pressure or reduced cooling capacity. The system also monitors condenser signal wiring, so a disconnection will be flagged and require attention.

Eaton In-Row Precision Cooling System Specifications

| Specification | Value |

| Electrical Input | |

| Electrical Consumption (Max) | 10 kW |

| Nominal Input Voltage(s) Supported | 208V AC |

| Nominal Input Voltage Description | 208V AC 60 Hz |

| Maximum Input Amps | 27 |

| Input Connection Type | 3-wire / 4-wire + Ground |

| Input Plug Features | 3-wire / 4-wire + Ground |

| Voltage Compatibility (VAC) | 208 |

| Input Frequency | 60 Hz |

| Cooling | |

| Airflow | 2,950 CFM |

| Cooling Type | Active |

| Cooling Capacity (BTUs) | 88,000 |

| Cooling Capacity (kW) | 25.8 |

| Refrigerant | R410A (Environmentally friendly, non-ozone-depleting) |

| Refrigerant Amount | 17.4 lb / 8.0 kg (Nominal) |

| User Interface, Alerts & Controls | |

| Front Panel LEDs | 7-inch color touchscreen |

| Physical | |

| Color | Black |

| Material of Construction | Aluminium, Steel |

| Shipping Dimensions (hwd / cm) | 227.98 × 104.14 × 124.46 |

| Shipping Weight (kg) | 317.51 |

| Unit Dimensions (hwd / cm) | 200 × 30 × 110 |

| Unit Weight (kg) | 198.22 |

| Environmental | |

| Storage Temperature Range | -40° to 140° F (-40° to 60° C) |

| Operating Elevation | 0–13,123 ft (0–4,000 m) |

| Audible Noise | 68 dBA |

| Operating Temperature | 4° to 115° F (-16° to 46° C) |

| Operating Humidity Range | 5 to 80% |

| Condensate Drain Pumps | Max distance 150 ft (45 m), max lift 26.5 ft (8 m) |

| Condensate Water Drains | 1/4 in. connection |

| Communications | |

| SNMP Compatibility | Yes, WEBCARDLXMINI card included |

| Features & Specifications | |

| Compressor Type | Rotary (Inverter Driven) |

| Sound Level (Noise) | 68 dBA @ 3000 CFM @ 1 meter |

| Fans (Type/Quantity) | 0–3000 RPM × 6 |

| Operation | |

| Operation Mode | Cooling, Standby, Off, Maintenance Mode |

| Supply Air Temperature (Celsius) | 18–27 °C (limited by heating load) |

| Applied Containment Types | Close / Open |

| Fan Controls | Automatic |

| Force Modes | Maintenance Mode, Rotation Mode |

| Power Redundancies | Single only |

| Temperature Unit Selections | °F; °C (default is °F) |

| Warranty & Support | |

| Product Warranty Period (Worldwide) | 1-year limited warranty |

Design and Build

The physical build is very sturdy, with steel and aluminum construction, insulated side panels to minimize external heat influence, and a height of 2 meters (42U) to match standard racks. At 198 kg, the unit is hefty but movable on its integrated casters, simplifying positioning during installation. Electrical connections can be routed from either the top or bottom, simplifying integration into existing cable management infrastructure.

The system is also designed to handle a wide range of conditions commonly found in most IT environments. It can operate in temperatures ranging from 4°C to 46°C, with humidity levels between 5% and 80%, and is rated for altitudes of up to 4,000 meters. So even high-elevation sites won’t see a decline in performance unless things get really extreme. For storage and shipping, it’s even tougher, with a range of -40 °C to 60 °C to cover both warehousing and transport. On the compliance side, it’s certified to UL 60335, CSA, and NOM standards. It meets FCC Part 15 Class A and RoHS standards, ensuring compliance with the key safety and environmental requirements for North America.

In regular operation, the system is also notably quiet. The sound is barely noticeable and blends into the background. Inside, the fans run smoothly without significantly adding to the lab noise, making the system easy to live with on a day-to-day basis.

Maintenance and Operational Functions

The interface is designed to display the most essential details immediately. The home screen gives you supply air temperature, return air humidity, dehumidification status, total fan speed, and cooling output as a percentage of capacity, all at a glance. There’s also a simple status indicator showing whether the compressor is running or in standby, along with straightforward on/off controls for the cooler itself. Even small features, like displaying the maximum fan speed limit on the same screen, make it easier to understand how the system is performing without having to dig through layers of menus.

Within the system’s control menus, you can define whether cooling is controlled based on supply air or return air temperature. Supply air control is the default, but return air control can be beneficial in situations where you want to control the unit solely based on incoming air. Temperature bands, humidity targets, and alarm thresholds are all configurable, allowing operators to adjust precision and response according to load stability and environmental sensitivity. The humidity controls focus solely on dehumidification; if you’re in an overly dry environment, the cooler won’t add moisture.

If you have more than one In-Row Cooler, the interface lets you configure group control directly on the unit. This includes defining master and standby units, scheduling rotation intervals to even out wear, and enabling “force on” redundancy. Hence, a standby unit takes over immediately if the master encounters a fault. These settings are easily accessible directly from the touchscreen, which is ideal because they are more likely to be used.

Maintenance Mode is also easily accessible on the home screen if it has been enabled in the settings. Turning it on activates the system’s full cooling output for 30 minutes, which helps clear heat from the hot aisle and makes servicing equipment more comfortable. Once the timer expires, the unit automatically returns to its normal operating mode.

The data menu displays detailed system parameters for technicians, while the graph menu tracks historical trends for parameters such as temperature, humidity, and refrigerant pressure. There’s also an alarm menu that displays active faults in real-time and maintains a history of past ones, complete with possible causes and suggested fixes. That makes it much easier to determine if the issue is something your team can handle on the spot (such as clearing a blocked airflow) or if it’s time to bring in an HVAC contractor.

Day-to-day maintenance is also relatively simple. Check that setpoints are being met, review the alarm log, ensure the rotation schedule is functioning, inspect for leaks, and clean or replace filters approximately every six months. Because so much operational and historical data is accessible directly from the interface, the unit encourages proactive checks rather than reactive fixes.

Web Management Interface (PowerAlert Device Manager)

The unit is managed through Eaton’s PowerAlert Device Manager (PADM), a browser-based interface that provides complete visibility into system health, environmental conditions, and control options. While the interface itself is relatively lightweight, it surfaces all the critical information administrators need for day-to-day monitoring and long-term maintenance.

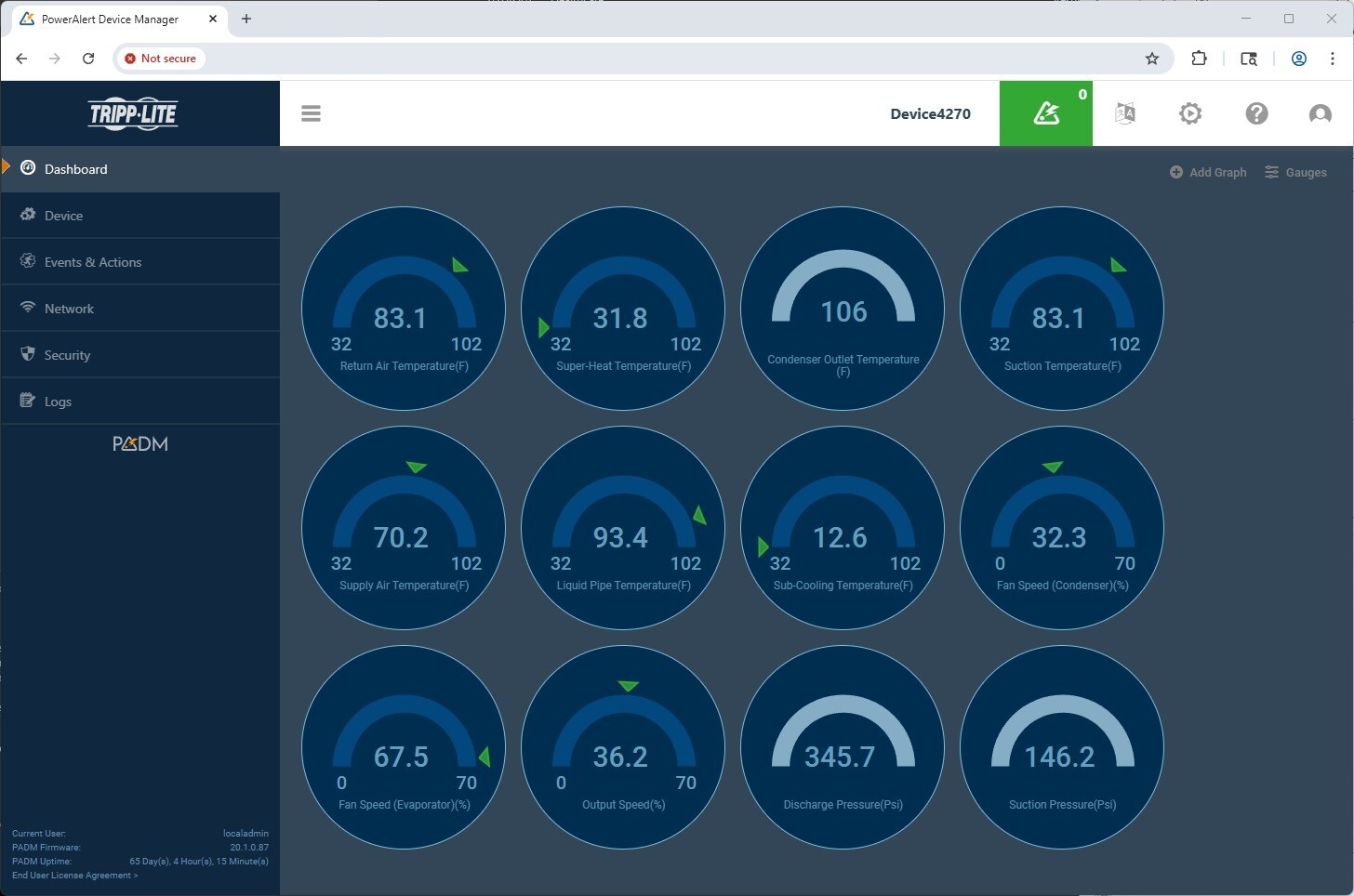

Dashboard Overview

The main dashboard displays real-time gauges for key operating metrics, including return/supply air temperatures, liquid pipe and suction temperatures, condenser outlet temperature, subcooling and superheat values, fan speeds, and compressor pressures.

These gauges provide a quick, at-a-glance health check of both air-side and refrigerant-side performance, enabling the fast detection of anomalies without requiring in-depth analysis.

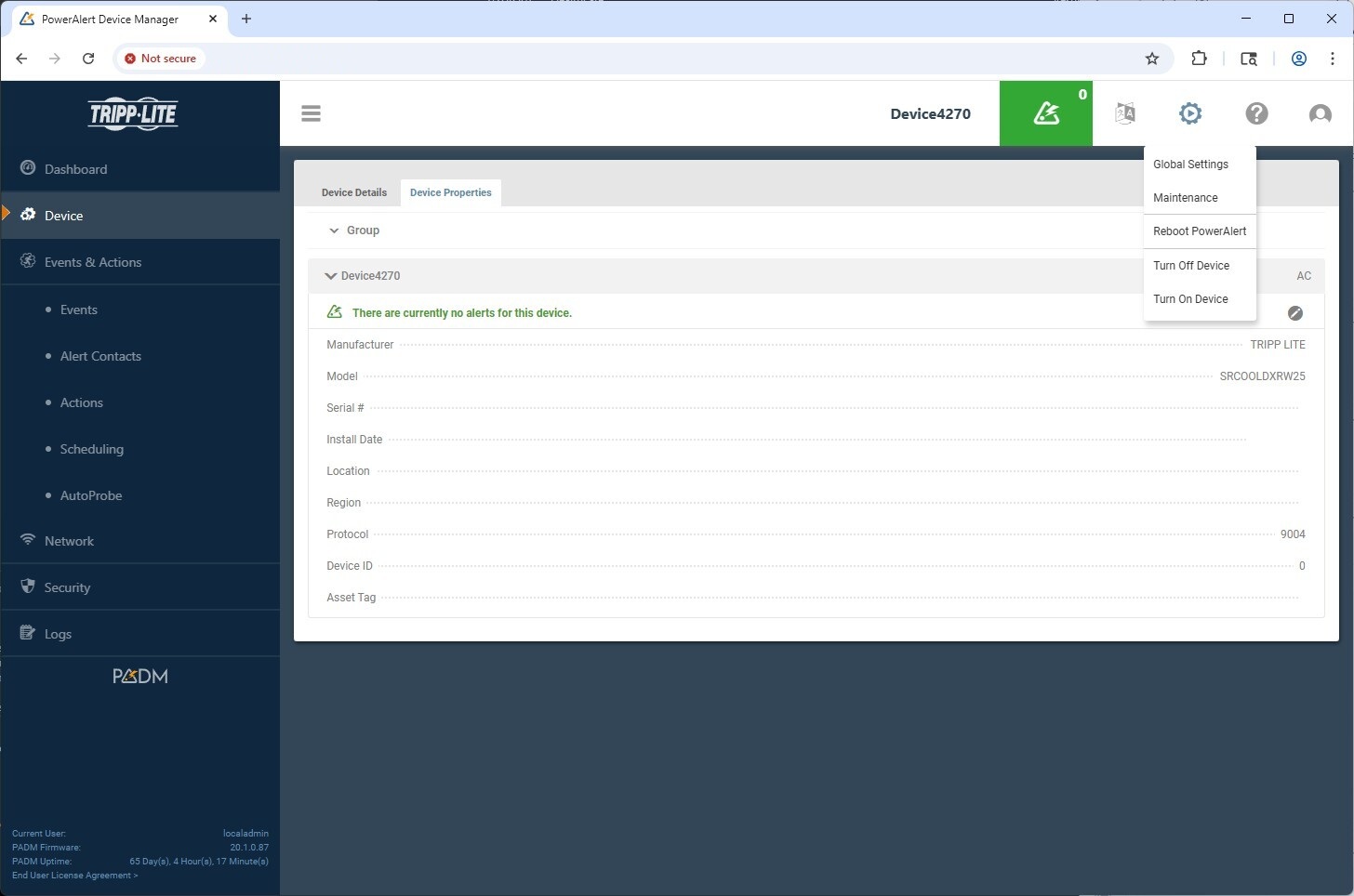

Device Details & Properties

The Device menu expands into detailed properties for the unit, including manufacturer, model, serial number, firmware version, and operating mode. In this case, the SRCOOLDXRW25 reports firmware version 9.82 with no current fault conditions. Device properties also support tagging with custom fields, such as installation date, location, and asset tag, which are helpful for fleet or multi-site environments.

From this menu, administrators can also initiate actions such as turning the device on/off, rebooting the PowerAlert controller, or scheduling maintenance.

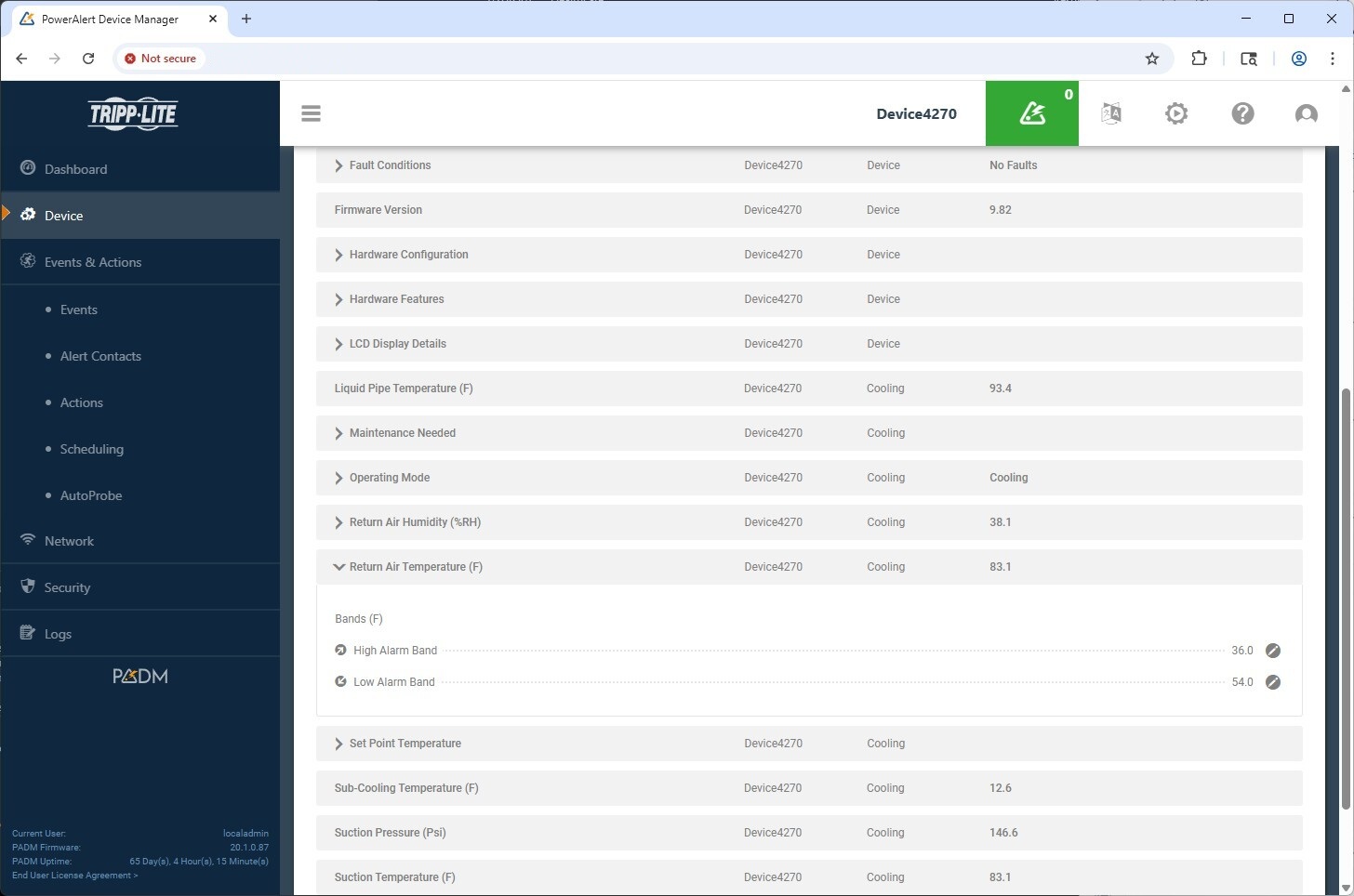

Environmental Monitoring

Environmental tracking is built in, with return air humidity (%RH) and multiple temperature points captured continuously. Alarm bands can be configured (for example, high temperature at 54°F and low at 36°F in the test system) so that admins receive alerts before conditions drift outside acceptable ranges.

Events, Alerts, and Actions

Beyond monitoring, PowerAlert Device Manager includes event logging and alert contact management. This allows users to configure email or SNMP trap notifications for threshold breaches, maintenance reminders, or hardware faults. Automated responses (such as triggering external relays or adjusting operating modes) can be tied to these alerts, adding resilience to cooling management strategies.

Security and Network Settings

The interface includes basic network and security controls, allowing the unit to be assigned a static IP address, configured for SNMP, and enabled with user authentication for access control. While the connection defaults to HTTPS, TLS can be enabled for secure access in production deployments.

Temperature Stability in Lab Conditions

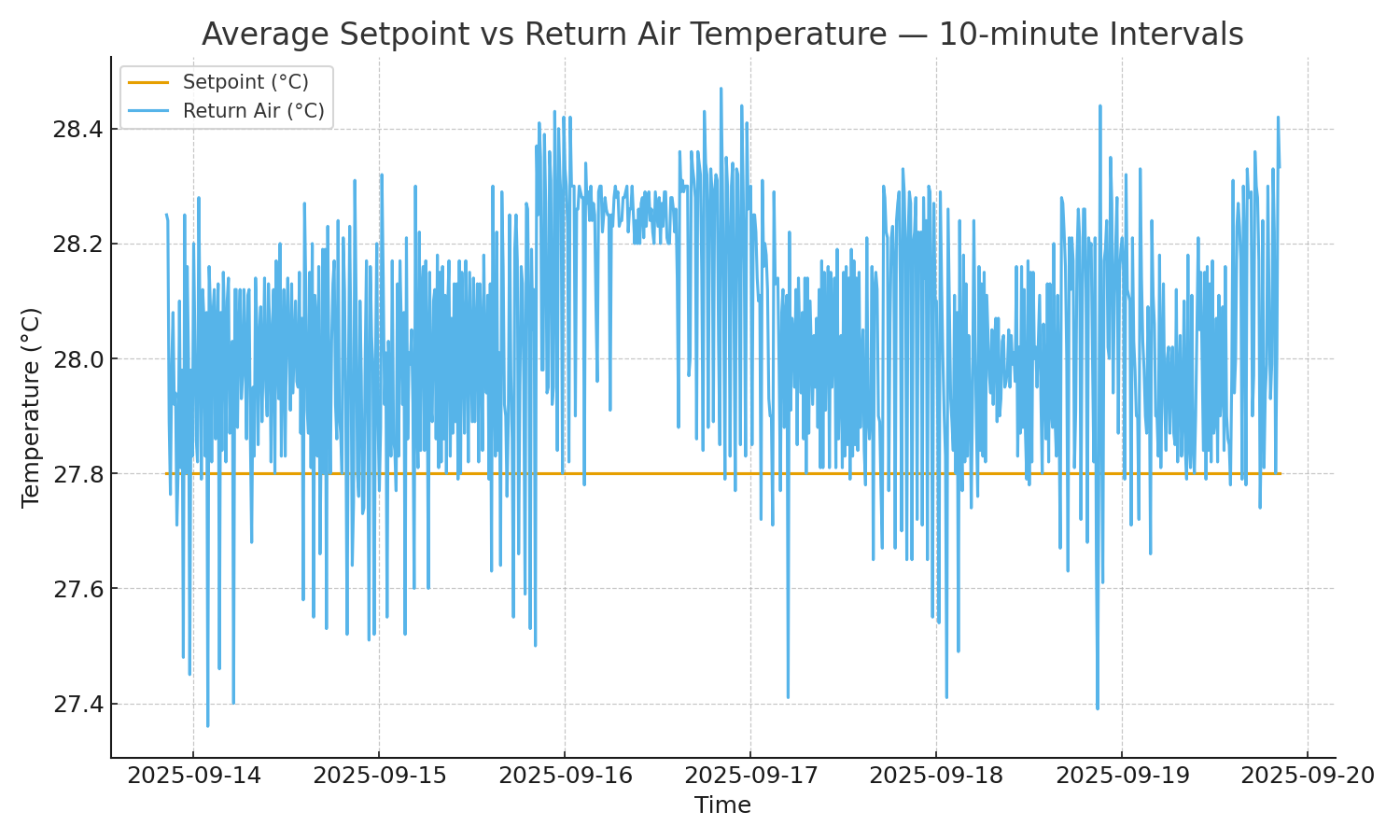

To better understand how our unit maintains environmental balance, we tracked average return air temperature against the configured setpoint over several months in our lab. The chart below illustrates this comparison, with the setpoint holding steady at approximately 27.8 °C while return air temperatures fluctuated based on load conditions.

What stands out is that, despite variations in workload across servers and test platforms, the temperature swing remained within approximately 1°C of the set point. This reflects the normal dynamics of our lab environment, where heat loads fluctuate throughout the day. The takeaway is not a measure of cooling capacity or efficiency, but rather confirmation that the in-row unit consistently holds the room within a very narrow band around the desired temperature.

Such stability is crucial for high-density environments, where sudden spikes or prolonged drift could compromise equipment reliability. Even under variable demand, the system demonstrates tight thermal regulation that should reassure operators managing sensitive workloads.

Real-World Cooling Example

With a 25.8 kW (88,000 BTU/hr) rating, the unit delivers approximately 20–21 kW of usable cooling capacity once a safe margin (≈approximately 20% headroom) is factored in. In practice, this supports two high-density racks at 10 kW each, or up to four racks at 5 kW each when airflow containment is in place.

Most enterprise deployments plan for this capacity in an N+1 redundant configuration, ensuring that if one unit is taken offline for maintenance or fault, the remaining systems can sustain the IT load without incurring thermal risk. This redundancy model makes the SRCOOLDXRW25 well-suited to modular scaling as additional racks come online.

Another practical consideration is form factor. The unit’s 11-inch width allows it to slot between racks without consuming a full cabinet. When deployed in pairs, such as one every 2 to 4 racks, two units together only occupy about the same width as a single 24-inch rack cabinet. This means redundancy and cooling coverage can be achieved with minimal sacrifice of valuable floor space.

Conclusion

The Eaton In-Row Precision Cooling System is ideal for environments where rack-level control and space efficiency are as important as raw cooling power. With its slim in-row footprint, DX cooling with inverter-driven compression, and EC fan precision, it is designed to keep heat in check at the source while avoiding the inefficiency of room-wide air handling. The touchscreen interface makes everyday operation, system adjustments, and even multi-unit coordination straightforward, resulting in a minimal learning curve. In day-to-day use, the system also runs surprisingly quietly. Even with the condenser running, it blends into the background without being distracting.

For IT managers who need to keep energy use in check while maintaining redundancy and uptime, all this functionality is a welcome package. At the same time, the Eaton In-Row Precision Cooling System is not a “one system cools it all” solution. With 25.8 kW of capacity per unit, it is best suited for high-density rows, mixed-density rack layouts, or edge facilities where targeted cooling is required without requiring an overhaul of the building’s HVAC system. As long as facilities teams stay on top of basic upkeep, such as keeping filters clean, monitoring alarms, and maintaining the outdoor condenser, this unit will deliver effective, consistent, and predictable cooling performance where and when it is needed most.

Amazon

Amazon